01R & D capabilities

The company has R & D staff of 30 people, full-time engaged in the casting process design process, with gold proprietary technology means to ensure the development of new products to meet the high quality requirements of customers; at the same time the use of 3D printing technology, to help customers product design updates up-front verification, and customer realization Double wrap the true sense.02Technological design

In the casting process design new product development process, the full use of CAE simulation software for solidification optimum gating system design choices, in order to shorten the development cycle purposes.

03Chemistry research and development

The company in May 2016 will test the physical and chemical Xian chamber become independent chemical application R & D room, its main functions: based on industry standards and corporate production process, silica sand, tree, dark, curing agent, coatings, paints and other raw materials off the chain technical indicators for testing, to achieve control of raw materials; to factory surface spray Coated product quality home inspection, home warranty CE meet quality requirements of customers products; Yi said with harsh economic security standards, improve or seek to develop more efficient, cheap bad insured chemical alternatives.043D printing technology research and development

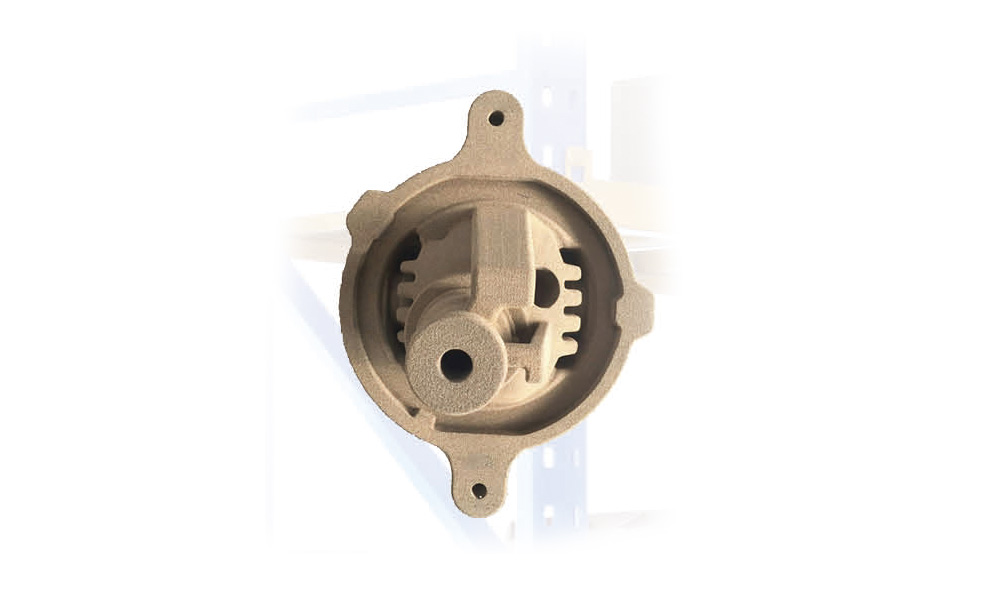

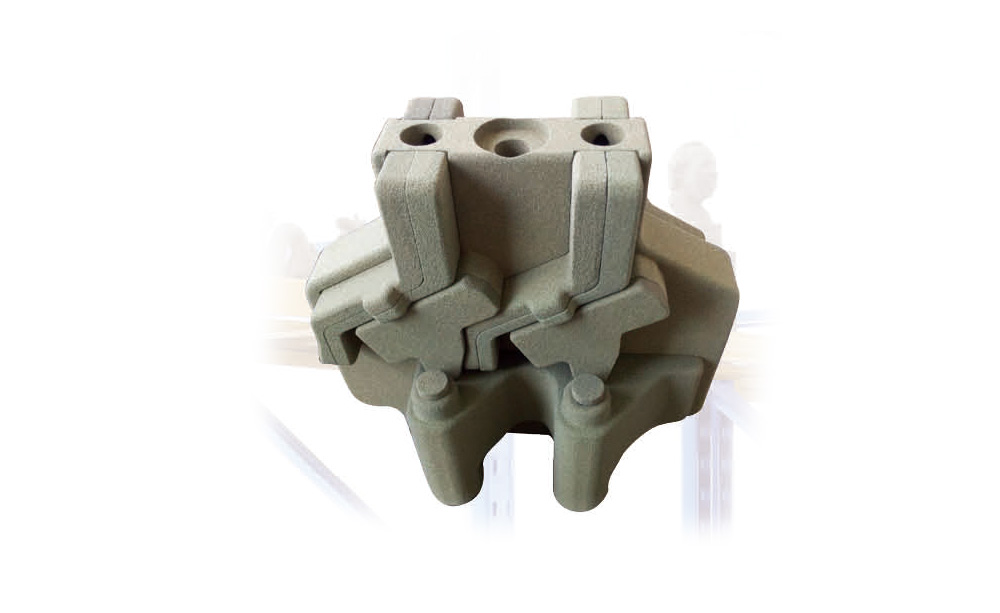

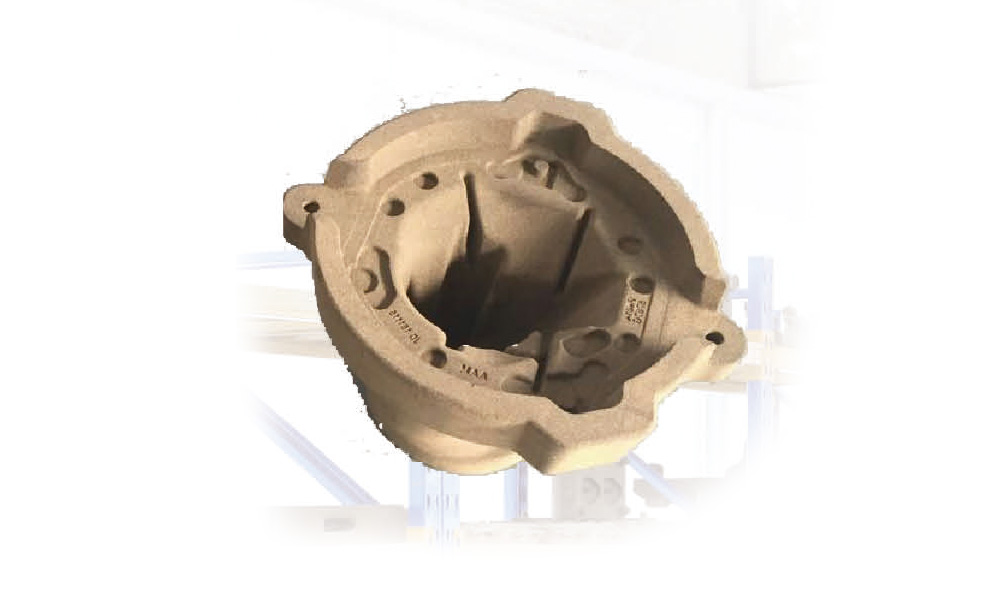

In the new product development, the introduction of the German company Bolv Man reverse engineering 3D scanners (smartSCAN 5M), for the detection of molds and products as well as ancillary products WH hair; while the introduction of Germany's advanced 3D voxeljet sand core printer ( VX2000 (forming box 2000x1000x1000mm), VX200 (molding box 300x200x150mm)), applied to the direct Print furan / phenol cool sand core / type; this 3D printing technology is mainly used for rapid development of new products, as well as direct verification simulation process optimization in small ink, high-end, complex products.

053D printing samples show